Application

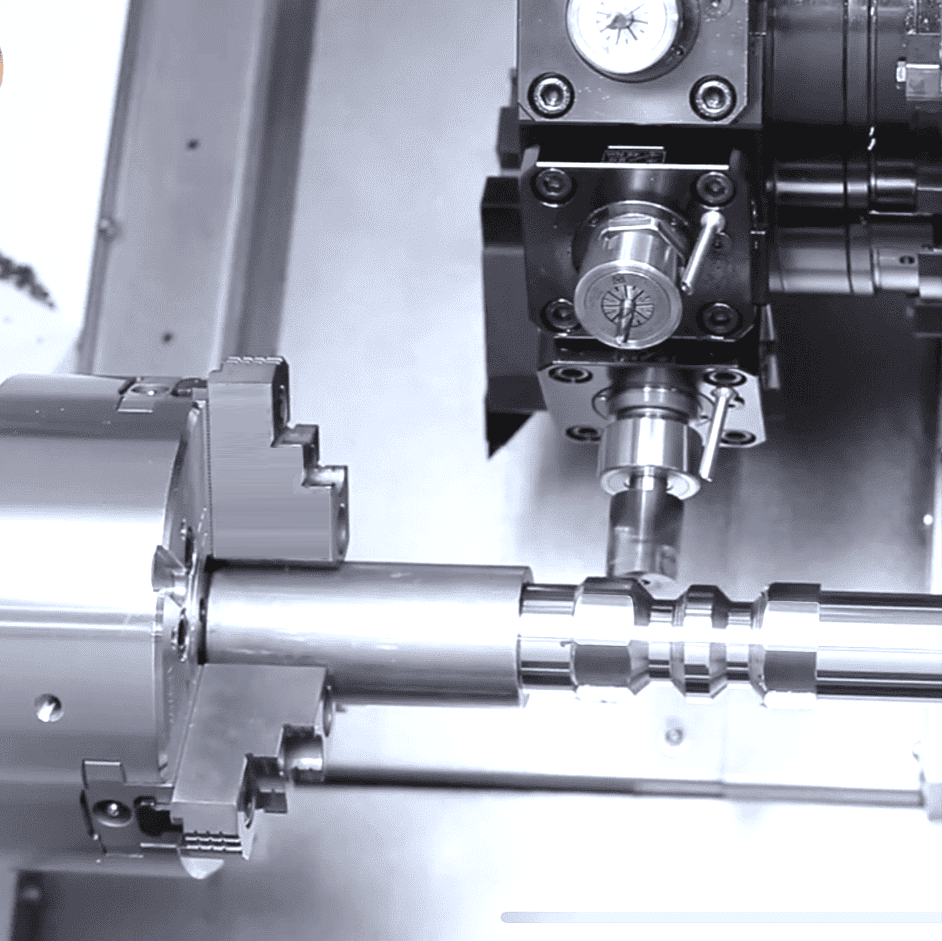

Multi-Axis Turning Milling Center

Multi-axis turning-milling machine is a CNC machining system that integrates turning and milling functions. Equipped with multiple spindles and live tool turrets, it enables simultaneous multi-process machining, significantly enhancing productivity and precision.

Compared to traditional machines, this type of equipment can complete complex part machining in a single setup, reducing tool changes and re-clamping errors. It is especially well-suited for high-precision and high-volume production demands.

This machine is capable of performing a wide range of operations, including inner and outer diameter turning, end-face machining, grooving, drilling, tapping, side milling, and curved surface processing. It is widely used in industries such as automotive components, aerospace parts, medical instruments, and electronic communication devices.

Common configurations include dual spindles, multiple tool turrets, and various live tooling setups, allowing simultaneous machining on different sides of a workpiece—dramatically shortening overall cycle time.